A bit of background…

Mafdel positively driven monolithic belts have been with us for a number of years and they have been a major game changer when taking belt hygiene on to higher levels. Experience and confidence in the market has grown and most major conveyor belt manufacturers have a product in their range that is monolithic or, at least, fulfils the role of a hygienic monolithic belt. Industry has also embraced the monolithic belt and many meat and poultry factories will now have a number of these incredibly hygienic and environmentally friendly belts in place.

The word monolithic describes an ‘unchanging structure’ or ‘single material’ so, any belt that has more than one component for example, a belt containing cords, is not actually monolithic but a reinforced or dispersed cord type and this doesn’t really achieve the goal of removing fabric contamination from food manufacture.

When comparing the two types, it’s important to understand the differences and consequential advantages of working with truly monolithic belts. It’s also important to know that truly monolithic and dispersed cord belts work in significantly different ways. Understanding this fundamental difference is important to get the best from a Mafdel belt. Working with a truly monolithic belt means that the joining method is simpler, quicker, is totally free from fabric and provides an opportunity to create open, more hygienic and less expensive conveyors.

How do they work?

Unlike corded types, truly monolithic (no fabric or cords) should NEVER be tensioned. So, how does a zero-tension monolithic belt actually work without reinforcing cords?

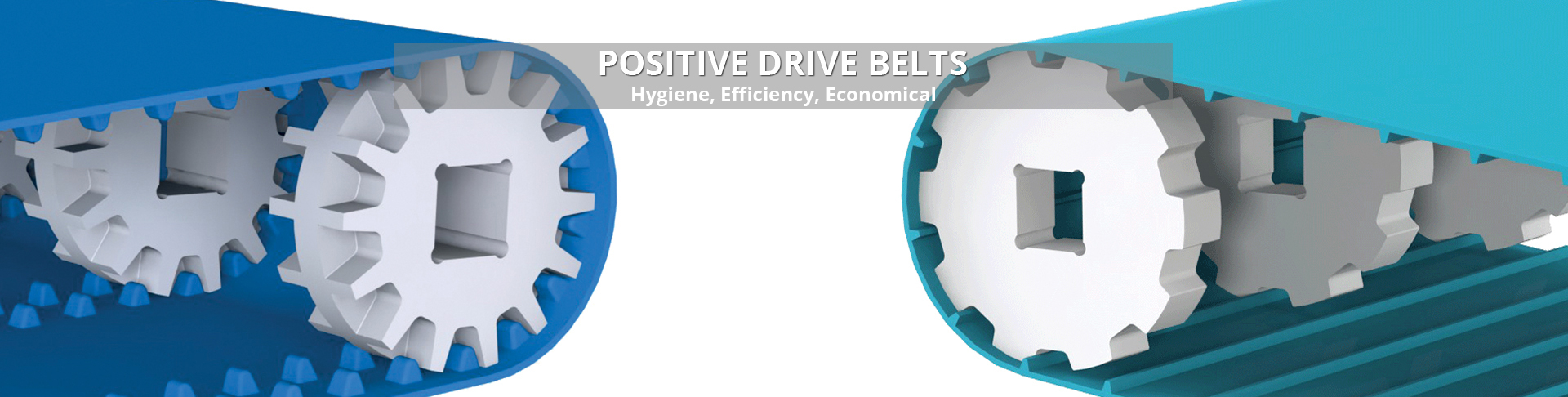

All belts elongate to a greater or lesser degree, either with applied pretension or through elongation in operation due to the applied load. In the case of a Mafdel positively driven monolithic belt, it is designed to elongate up to 2.5% to achieve its full load capacity during operation and then relax back to its original state when the load is removed. This principle requires a feature where the tooth pitch of the belt is 2.5% less of that of the sprocket. This means that the sprocket allows the belt pitch to change according to load and is a key design feature and will work like this for many years.

To illustrate this, if you take a close look at the photo of a Del/Drive 25 above, you’ll notice that the tooth at the bottom of the sprocket is in contact with the drive bar on the belt but, as you go clockwise, the gap between the drive bar and the tooth becomes progressively bigger. This is because the pitch of the belt is smaller than the pitch of the sprocket. If you apply the aforementioned 2.5% tension, all teeth will engage and the belt is then at full power. Reduce the load, the belt pitch reduces and tooth contact reduces again. The load creates the tension between it and the drive sprocket.

The key principle is that the zero tension allows the belt to ‘creep’ on the sprocket during elongation, allowing the movement of the teeth in the sprocket. For a truly monolithic belt, this is essential.

So, what happens if I tension a positively driven monolithic belt?

Well, two things happen. firstly, the applied pre-tension takes the place of available load capacity so, when you tension, the belt is already heading nearer to its maximum load capability. When you then add the load to be conveyed the belt is overloaded with the belt tooth pitch being extended longer than the sprocket pitch. This results in the belt jumping the sprockets.

The other issue is that the belt will no longer drive against the faces of the drive bars and has now become a friction drive where the belt is now driven by the top of the sprocket tooth and the back of the belt. This hinders the movement of the sprocket against the back of the belt. If the back of the belt cannot move against the top of the sprocket, there is a high risk that the teeth may run over the top of the teeth and again, you have a jumping belt. If you remove the pre-tension and provide some catenary sag, the jumping disappears, and the belt runs as it was designed to do.

Mafdel truly monolithic belts offer many advantages over their fabric reinforced counterparts.

If you want to discuss this further, contact an expert at Mafdel.