Frequently asked questions

Technical data

What do the colours mean on your belts and conveyor belts?

The colour identifies the type of material: composition, hardness, suitability for food contact, in addition to whether or not there is internal reinforcement.

White, ivory and blue are the colours most often used in the food industry.

What are the different product hardnesses used for?

A harder belt can accommodate greater loads with lower elongation.

However, a more flexible belt can accommodate smaller roller diameters.

Grip for transported products is higher on more flexible belts, but lower grip on a harder belt on the skid plate lets you increase the load.

The choice for the best belt is a matter of compromise and therefore depends on application characteristics.

How can I choose the right product for my application?

Customer satisfaction is a priority: Mafdel focuses all of its expertise on your applications.

Several solutions are available so that you can choose the product that is best suited to your needs:

- The selection guide: it lets you make a first product choice for your application

- Our technicians: they are there to answer your different problems and provide you with perfectly suited solutions

- Our research department is also available to design custom products for your applications and meet your expectations.

Conveyor belts

What is a conveyor belt?

A conveyor belt allows for continuous movement of merchandise on a horizontal, inclined or declined conveyor.

The upper surface of the conveyor belt is in direct contact with the transported product, and the lower surface is in contact with the conveyors mechanical components.

Conveyor belts are used in many food or standard industries.

Mafdel offers a range of mono-material conveyor belts made from polyurethane (PU) or polyester (PE), for a broad range of industries.

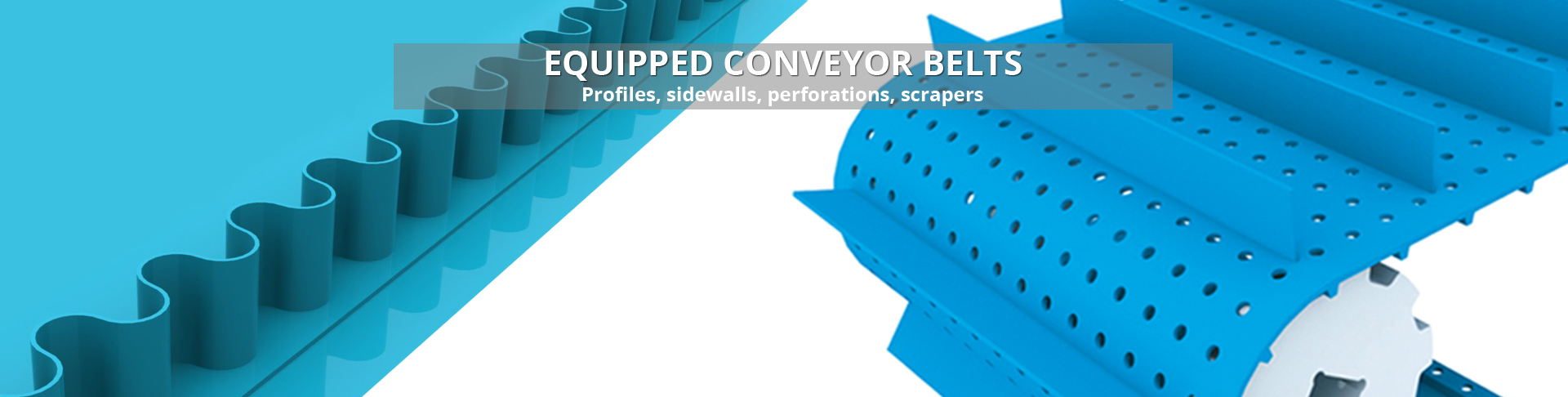

Bespoke conveyor belts can be created according to need: profiles (flat or rounded), sidewalls, perforations, etc.

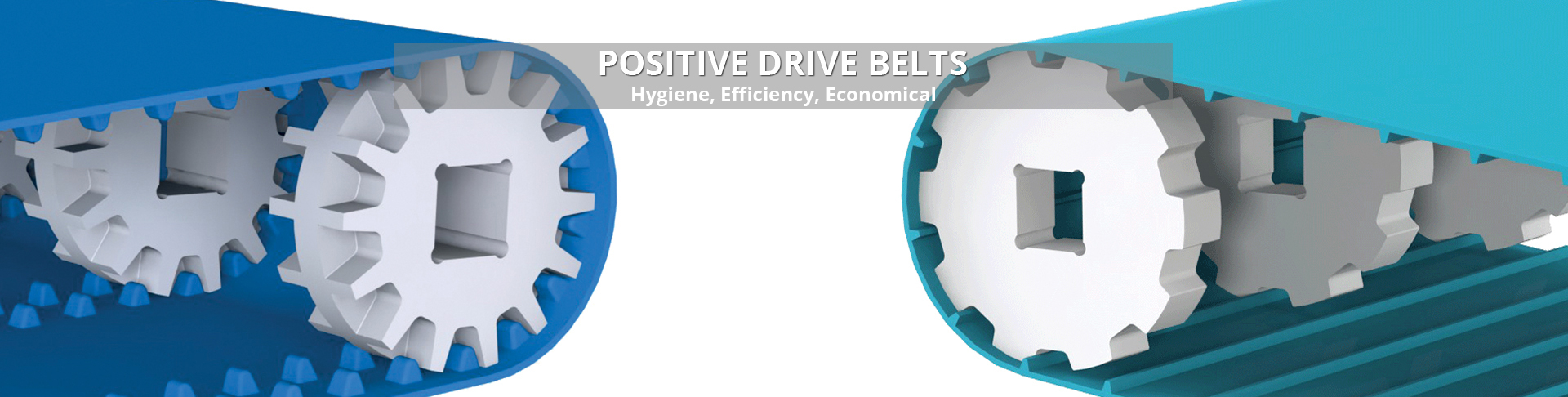

What is a positive drive conveyor belt?

A positive drive conveyor belt combines the benefits of mono-material belts and modular belts without the inconveniences such as poor hygiene or mechanical wear.

Manufactured from polyurethane or polyester elastomer, positive drive belts from the Mafdel range are exclusively mono-material (no textile threads) and are an optimum solution for agri-food industries.

The lower surfaces have teeth moulded into the belt itself which ensure perfect interlocking on the sprockets, while avoiding any risk of belt slippage and bacteria traps.

Positive drive belts offer a maximum level of hygiene and decrease health risks.

Mafdel offers three positive drive belt families that meet most needs.

> More details in the positive drive belt section

What is the difference between smooth mono-material belts and positive drive belts?

Smooth mono-material belts guarantee an optimum level of hygiene thanks to their perfectly smooth upper surface that makes cleaning easy. However, they drive under tension, but this in no way eliminates the risk of slippage in oily and wet conditions.

A Positive belt drive doesn’t rely upon drive through tension on pulleys but through the physical engagement of drive teeth on toothed pulleys.

This system eliminates any risk of belt slippage, even in oily conditions. Positive drive belts do not require tension mounting and offer a perfectly smooth upper surface guaranteeing an optimum level of hygiene.

Therefore, positive drive belts have all the advantages of mono-material smooth belts without the risk of slippage, even in oily, wet conditions.

> More details in the positive drive belt section

Why use a conveyor belt with an antimicrobial treatment?

Antimicrobial treatment is particularly suited to agri-food industries and helps maximise the level of hygiene:

- Prevents bacterial growth

- Eliminates the risk of contamination for transported products

- Reduces odour development

- Optimises food safety

- Improves cleaning and disinfecting procedures.

How to track a conveyor belt?

To guide a smooth conveyor belt there are two possibilities:

- Use crowned drums which are very slightly bigger in diameter in the centre than at the sides

- Set up a central tracking guide or two longitudinal guides on the lower surface of the belt.

In both cases, all of the drums must be perfectly parallel (motor, return and back up rollers).

Positive drive belts are very easy to guide:

- For a DEL/DRIVE conveyor belt, we recommend using flanged sprockets. As the belt is not tensioned, the flanges help maintain the belt in the longitudinal axis. For wider gaps, it is recommended to add lateral guide pads.

- For a POSITIVEBELT conveyor belt, guidance is made automatically thanks to the drive sprockets.

- In the case of a DEL/SYNC conveyor belt, the channel on the conveyor bed ensures central tracking.

How to repair a conveyor belt?

Our mono-material conveyor belts can be repaired on site in case of damage by using a hot air welding repair.

If there is a cut:

– Make a 45° bevel on both sides of the cut

– Using a hot air welding gun, fill the bevelled cut with a melted plastic seam that is of the same quality as the belt

– Use a cutter to level down the excess material.

In cases where the belt has a heavily damaged area, it is possible to replace an entire section. Our thermowelding jointing techniques allow for this operation to be carried out very quickly on site.

How to weld a conveyor belt?

All belts can be endless welded or delivered open for on-site welding.

Conveyor belts can be welded in two ways:

- Thermowelding: We offer our end-to-end welding kits. Option for hot air welding (adding material).

- Fasteners: Belts can also be jointed using polyurethane or stainless still clips (recommended for pulley diameters greater than 120 mm). This type of jointing is highly recommended for frequent assembly/disassembly or for repair.

> See more details in the joints and tools section

Belts

How are belts tensioned?

Exerted tension depends on the type of belt used (from 0.5% to 8% for Mafdel belts – see the catalogue for recommendations).

There are two ways to apply tension to a belt:

- The conveyor is equipped with a suitable tensioning system: In this case, the tensioner must be set to the minimum, install the belt and adjust the tensioner to apply the belt tension.

- The conveyor is not equipped with a tensioning system, or it is insufficient: In this case, you must use pre-tensioning tools comprising a winch and two tightening jaws, which will enable you to pull the belt ends together and then apply the welding process.

If the belt is reinforced, you must take care not to apply excessive force, which could destroy the reinforcement.

How are belts measured?

In the case of standard configuration (belt extended between two pulleys with the same diameter), the theoretical belt length is equal to the pulley circumference + (2x the centre distance).

For any other configurations, kindly send us a dimensional drawing of the installation.

In all cases, the tension system must be returned to its minimum position.

Our technicians are available to help you define your needs.

Why use reinforced belts?

Aramid reinforcement stops elongation on our round and v-belts.

This allows for use of long-length belts, while at the same time minimising the need for long travel tensioning devices. The maximum allowable load is also higher, especially with our overlap weld.

How do you weld a reinforced belt?

Our reinforced belts can be welded together in the same way as our non-reinforced belts, using just an iron and clamp. The aramid reinforcement on our belts is resistant to very high temperatures, it does not need the reinforcement to be removed at the joint before welding.

Both types of welds (end-to-end and overlap) can be used.

What is cogging used for on v-belts?

Cogging allows increased belt flexibility and therefore reduces the minimum pulley diameter.

Cogging cannot be used for driving using a cogged pulley.

In what case or cases should High Density Polyethylene (HDPE) runners be used?

HDPE runners offer excellent guiding for round or trapezoidal belts.

They also help improve the friction coefficient and therefore increase the transported load.

> See more details in the Belt runners section

What is the difference then between flat belts and conveyor belts?

Our definition:

– Flat belts have a width of less than 100 mm.

– Conveyor belts have a width greater than or equal to 100 mm.

Other questions

How do Mafdel products help achieve an optimum level of hygiene in the agri-food industries?

One of our priorities is to provide quality products that contribute to compliance with hygiene standards.

Our belts and conveyor belts in the agri-food range comply with the most stringent standards and offer characteristics that help attain an optimum level of hygiene:

- Our mono-material products do not have textile threads, which eliminates the risk of fraying

- Waterproof and rot-resistant products

- Easy to clean

- Resistance to chemical aggression: solvents, oils, fats, cleaning products, etc.

Using Mafdel belts and conveyor belts also helps satisfy HACCP process requirements.

What is the HACCP process?

The HACCP (Hazard Analysis Critical Control Point) process is a method intended to reduce the maximum number of sanitary risks in agri-food industries.

This method is based on 7 main principles aiming to control risks during the process and to analyse the hazards during verification of the effectiveness of the implemented system.

The Mafdel range of belts and conveyor belts helps provide an optimum level of hygiene to satisfy the requirements of this process.

This FAQ is updated over time with your questions. Please contact our technicians.